1、What Is a Pole-Mounted Transformer?

Pole-mounted transformers are essential components in modern power distribution networks. As their name suggests, these transformers are installed high above the ground, typically mounted on wooden or concrete utility poles. Their primary function is to step down high-voltage electricity from overhead transmission lines to lower voltages suitable for residential or rural area use.

Widely used by utility companies, pole-mounted transformers provide a reliable and cost-effective solution for delivering electricity safely and efficiently to homes and businesses. These outdoor transformers are elevated to reduce the risk of damage from floods and water accumulation, and their installation on poles makes maintenance easier for line workers using bucket trucks.

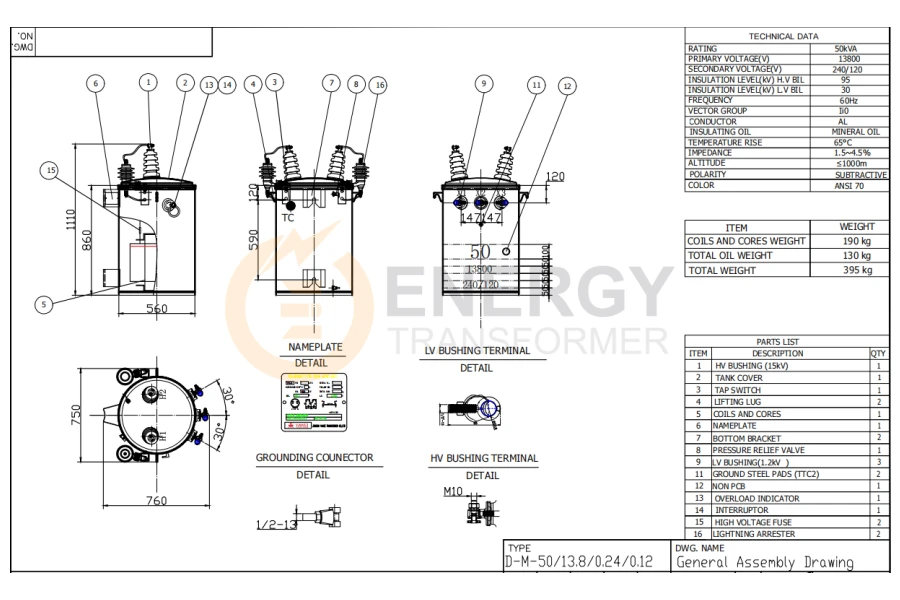

Typically, pole-mounted transformers come in capacity ranges from 10 kVA up to about 333 kVA, with most models not exceeding 250 kVA. They are mostly oil-filled for insulation and cooling, though dry-type variants also exist. Their compact and elevated design distinguishes them from pad-mounted transformers, offering a practical option for areas where underground utilities are less common.

In this guide, we’ll explore the key features, applications, and benefits of pole-mounted transformers, helping you understand why they are a crucial part of power distribution systems worldwide.

2、What Are The Types Of Pole Mounted Transformers?

Pole-mounted transformers come in various types and configurations, each designed to fulfill specific roles in the power distribution system. Understanding these types helps utilities and customers choose the right transformer for their needs. The two main categories of pole-mounted transformers are Conventional Transformers and Completely Self-Protected (CSP) Transformers. Within these, both single-phase and three-phase models are available depending on the application and power requirements.

(1.)Conventional Pole-Mounted Transformers

Conventional transformers are characterized by having two sets of primary bushings and consist of components such as the transformer body, oil tank, high and low voltage bushings, grounding devices, and connection terminals. These transformers are the most common type found in pole-mounted applications and hold an important place in power distribution.

They do not include built-in protection devices like lightning arresters or fuses, which makes them generally more cost-effective compared to CSP transformers. This design is suitable for areas where external protection can be installed separately and where budget constraints are a factor. Conventional transformers are typically used in residential neighborhoods, commercial buildings, and less critical infrastructure where the risk of electrical faults is relatively low.

(2.)Completely Self-Protected (CSP) Pole-Mounted Transformers

CSP transformers are equipped with integrated protection devices such as lightning arresters, fuses, and circuit breakers, which allow them to self-protect against faults caused by lightning strikes, short circuits, and other electrical anomalies. These built-in protections help prevent damage to the transformer and distribution lines, increasing system reliability.

CSP transformers simplify installation and maintenance since external protection devices are not required. They are widely used in applications where safety and reliability are paramount, such as critical infrastructure or areas with frequent electrical disturbances. The advanced protection features do come at a higher cost compared to conventional transformers, but the enhanced safety and reduced downtime often justify the investment.

(3.)Single-Phase vs. Three-Phase Pole-Mounted Transformers

Pole-mounted transformers are also divided by their phase configurations:

-

Single-Phase Pole-Mounted Transformers are commonly used in residential settings. Each home typically has its own single-phase transformer. They operate with one active conductor and a neutral wire, providing power suitable for household electrical loads. Single-phase transformers deliver a lower power level and are simpler in design, making them the most widespread for individual homes.

-

Three-Phase Pole-Mounted Transformers are more common in commercial and industrial applications where larger amounts of power are needed. These transformers consist of three separate windings and deliver balanced power loads, improving efficiency for heavy-duty electrical equipment. Three-phase transformers are essential for high-capacity power transmission and conversion in complex electrical networks.

Energy Transformer offers a wide range of both single-phase and three-phase pole-mounted transformers, designed to meet diverse customer needs with reliable quality and advanced protection options. Whether you require conventional or CSP types,Energy is a trusted manufacturer that delivers efficient and cost-effective pole-mounted transformer solutions.

3、Working Principle of Pole-Mounted Transformers

Pole-mounted transformers are essential components in electrical distribution systems, commonly seen mounted on utility poles in residential and small commercial areas. Their main function is to convert high-voltage electricity from power lines to a lower voltage suitable for use in homes and businesses.

How Do Pole-Mounted Transformers Work?

Pole-mounted transformers typically consist of two windings: the primary winding and the secondary winding. When an alternating current flows through the primary winding, it creates a magnetic field around the coil—a phenomenon known as mutual induction. This magnetic field induces a voltage in the secondary winding, which can be either stepped up or stepped down depending on the transformer design.

For example, utility pole-mounted transformers usually convert the high distribution voltage down to a standard 120/240 volts used by most homes and small businesses. This voltage transformation allows electrical power to be safely and efficiently delivered to everyday consumers.

4、Pole-Mounted Transformer Operation and Installation

Pole-mounted transformers are typically installed on concrete or wooden poles. This elevation helps to evenly distribute the generated power vertically along the transmission lines and keeps the equipment safe from ground-level hazards such as flooding or accidental contact.

Smaller transformers, usually under 5 meters in height, can be mounted securely on a single pole attached to a building, while larger units might require two poles for support. Their compact size and lightweight design make them preferred for ease of installation and maintenance.

Safe and Reliable Power Delivery

During operation, electric current passes through the inductive coils inside the transformer. These coils, connected to metallic cores, efficiently transfer electrical energy by focusing the magnetic field generated by the primary coil into the secondary coil. This process results in the conversion of voltage levels required for downstream applications.

Pole-mounted transformers are usually hardwired into the power grid via insulators and require careful handling during connection, often involving switching mechanisms to prevent sparks or faults.

Voltage Transformation in Power Distribution

At power generation plants, voltages can reach hundreds of thousands of volts for efficient long-distance transmission. Near residential areas, substations reduce these voltages to several thousand volts. From there, power travels via utility poles or underground conduits to neighborhoods. Pole-mounted transformers then step down the voltage to the final 120/240 volts that feed your home.

In many regions, electricians colloquially refer to these transformers as “pole pig” transformers, as a single unit often serves multiple households.

5、Key Components of Pole-Mounted Transformers

Pole-mounted transformers rely on several essential components that enable efficient voltage transformation and safe power distribution through electromagnetic induction.

Core and Windings: At the heart of the transformer lies the core made from high-permeability steel laminations that reduce energy loss. Wrapped around the core are copper or aluminum windings, which conduct electrical current and facilitate voltage conversion.

Oil Tank: Surrounding the core and windings, the oil tank provides physical protection and houses insulating oil. This oil serves dual functions — cooling the transformer and providing electrical insulation. The tank’s sturdy construction ensures durability against weather conditions, animals, and physical impacts while aiding in heat dissipation.

Insulating Oil: Crucial for transformer performance, insulating oil cools internal parts and prevents electrical discharge and oxidation. Regular testing of its dielectric strength, moisture content, and acidity is essential for maintaining transformer reliability.

Bushings: These high-quality insulating connectors link the transformer’s internal components with external power lines. Equipped with grading rings and made from advanced materials, bushings prevent electrical leakage and short circuits under high voltage stress.

Tap Switch: To maintain stable voltage output amid varying load conditions, the tap switch adjusts the transformer’s voltage. Available in manual and automatic versions, automatic tap changers allow real-time voltage regulation, enhancing power supply stability and reducing disruptions.

Oil Conservator Tank: Found in certain single-phase transformers, this tank accommodates the expansion and contraction of insulating oil due to temperature changes. It features a diaphragm or bladder that isolates the oil from air exposure, preventing contamination and preserving insulating properties.

Breathers: Breathers protect the insulating oil by absorbing moisture from incoming air, using desiccants like silica gel. The color-changing desiccant acts as a visual signal for maintenance needs, helping to avoid transformer failures and prolong service life.

6、How Many Homes Can a Single Pole-Mounted Transformer Supply?

The number of homes powered by a single pole-mounted transformer largely depends on the transformer’s capacity and the total electrical load demand of the connected residences.

Typically, a single-family home’s power consumption can range widely, especially if appliances like electric heaters, water heaters, dryers, or stoves are in use. Loads can vary from a few hundred watts up to 10-15 kVA or more. For example, a 15 kVA transformer can support the needs of one average household with typical electrical usage.

However, in neighborhoods where homes predominantly use gas-powered appliances (such as ovens, water heaters, dryers, and heaters), the electrical load per household is significantly lower. In such cases, a larger transformer — for instance, a 250 kVA pole-mounted transformer — can efficiently supply power to dozens of homes simultaneously, depending on the overall demand.

Typical Voltage and Configuration of Pole-Mounted Transformers

Pole-mounted transformers commonly operate at distribution voltages like 11 kV (primary) and step down to 400 V (secondary). Single-phase line voltage is usually around 230 V, while three-phase line voltage is 400 V. These transformers are often connected in a delta-wye (Δ-Y) configuration to the power grid to balance loads and ensure stable operation.

Transformer Capacity and Efficiency

The capacity of pole-mounted transformers varies, with common sizes ranging from 15 kVA to 250 kVA or more. Proper load balancing and correct sizing are key to achieving peak efficiency and reliable power delivery. A well-matched transformer minimizes energy losses and meets the power needs of the community without frequent overloads.

7、Key Maintenance Tips for Pole-Mounted Transformers

Maintaining pole-mounted transformers is crucial for ensuring reliable power delivery and safety for both workers and the community. Effective maintenance extends transformer life, prevents failures, and reduces downtime. Here’s an overview of essential maintenance tasks:

-

Visual Inspection

Conduct frequent visual checks to spot oil leaks, rust, cracks, or physical damage. Early detection of these issues prevents serious faults and costly repairs. -

Checking Oil Condition and Level

Transformer oil acts as an insulator and coolant. Regularly verify the oil level and test its condition to detect moisture, acidity, or contamination that could compromise performance. -

Oil Treatment and Filtration

Over time, oil quality degrades due to contaminants like water and gases. Periodic filtration and dehydration help restore insulation properties and improve cooling efficiency. -

Securing Electrical Connections

Loose or corroded connections can cause overheating and electrical arcing. Regularly tighten and inspect connections, including bushings and tap changers, to maintain system stability. -

Cleaning External Components

Accumulated dirt and debris can block cooling fins and radiators, reducing heat dissipation. Clean the transformer exterior and cooling surfaces regularly to ensure optimal temperature control. -

Load Management

Monitoring the transformer load helps prevent overloading, which can lead to premature failure. Use load sensors or monitoring systems to maintain operation within rated limits. -

Inspecting Bushings and Insulators

Check bushings and insulators for cracks, contamination, or damage. Faulty insulators can lead to short circuits and reduce transformer efficiency.

By implementing these maintenance practices consistently, utilities can enhance transformer reliability, safety, and lifespan while minimizing operational disruptions.

8、What Is the Average Price of a Pole-Mounted Transformer?

The cost of a pole-mounted transformer varies significantly depending on the phase type, capacity, brand, and certifications. On average, you can expect to pay between $500 and $4,500 for most standard residential and light commercial models.

💡 Single-Phase Pole-Mounted Transformers

For basic applications such as rural homes or small facilities, single-phase units typically cost between $600 and $3,800. These models are often used where the power demand is relatively low and three-phase systems are unnecessary.

⚡ Three-Phase Pole-Mounted Transformers

Designed for commercial and industrial use, three-phase pole-mounted transformers generally range from $1,200 to $5,000, depending on voltage rating and kVA capacity. These units are ideal for areas with higher load requirements and balanced power distribution needs.

🏭 High-End Industrial Models

Heavy-duty pole-mounted transformers from leading global brands like ABB, Siemens, or Toshiba can cost anywhere from $10,000 to $40,000. These high-spec models are built for maximum reliability, often feature advanced insulation systems, and comply with stringent international standards.

9、Who Are the Top Pole-Mounted Transformer Manufacturers?

When it comes to reliability, safety, and performance, choosing a trusted pole-mounted transformer manufacturer is critical. Below are some of the leading names in the global market:

🔹 Siemens (Germany)

A pioneer in smart grid technology, Siemens produces energy-efficient pole-mounted transformers designed for sustainability and long-term reliability. Their CAREPOLE line uses biodegradable insulating fluids and compact designs.

🔹 ABB (Switzerland)

Known for innovation in electrification, ABB offers pole-mounted transformers tailored for both urban and rural networks. Their solutions meet global standards and support smart grid integration.

🔹 GE Grid Solutions (USA)

GE provides pole-mounted transformers for primary and secondary distribution with a focus on durability, high efficiency, and remote monitoring capabilities.

🔹 Schneider Electric (France)

Schneider delivers compact, safe, and eco-designed pole-mounted units that are widely used in commercial and industrial networks across the world.

🔹 Mitsubishi Electric (Japan)

With a focus on high-voltage distribution, Mitsubishi’s pole-mounted transformers are engineered for stable performance in demanding environments.

🔹 Hyundai Electric (South Korea)

A division of Hyundai Heavy Industries, this manufacturer offers robust pole-mounted transformer solutions for infrastructure and utility-grade applications.

🔹 Energy Transformer (China)

As a trusted Chinese OEM manufacturer, Energy Transformer provides cost-effective, high-quality pole-mounted transformers with global certifications such as CE, UL, and CSA. Ideal for distributors and utility companies seeking customized and scalable solutions with fast delivery and full after-sales support.

🔹 Factory-Direct Pricing and OEM Options

Chinese manufacturers such as Energy Transformer offer competitive pricing starting around $1,600 for single-phase units and up to $5,500 for three-phase configurations. Despite the lower price, these transformers often carry CE, UL, or CSA certifications and undergo rigorous testing.

10、Conclusion

Choosing the right type of transformer is a strategic decision that impacts not only the efficiency and reliability of your power distribution system but also its safety, maintenance needs, and environmental compatibility. Pole-mounted transformers are particularly well-suited for rural and low-density areas, offering a cost-effective and practical solution for dependable power delivery. These compact units play a vital role in supporting grid connectivity and community infrastructure.

Understanding the key components and functions of pole-mounted transformers helps demystify their operation and highlights their engineering efficiency. Whether you’re upgrading your electrical network or planning a new installation, selecting a reliable manufacturer is essential.

Energy Transformer, a certified Chinese OEM manufacturer, offers a full range of pole-mounted transformers built to global standards, including CE, UL, and CSA certifications. We provide tailored solutions for single-phase and three-phase needs, with fast delivery and technical support.

📩 Contact Energy Transformer today for expert technical consultation, product catalogs, and custom transformer solutions that fit your project requirements.